Solutions for greater process reliability in automated manufacturing

This year at EMO, HEIDENHAIN is showcasing the TD 110 tool breakage detector for in-process tool inspection. This includes a live demo in conjunction with the StateMonitor machine data collection software. But even if a tool isn’t broken, it still can’t be used if it is too worn or if its cutting teeth are damaged. To detect these issues, HEIDENHAIN also offers the VT 121 vision system and the VTC 1.4 software for tool inspection. Tool inspection, in turn, requires having the correct tool in the machine and a tool table containing the correct data. One way of achieving this is to connect the HEIDENHAIN control to an external tool data management system, a service provided by the HEIDENHAIN Service team.

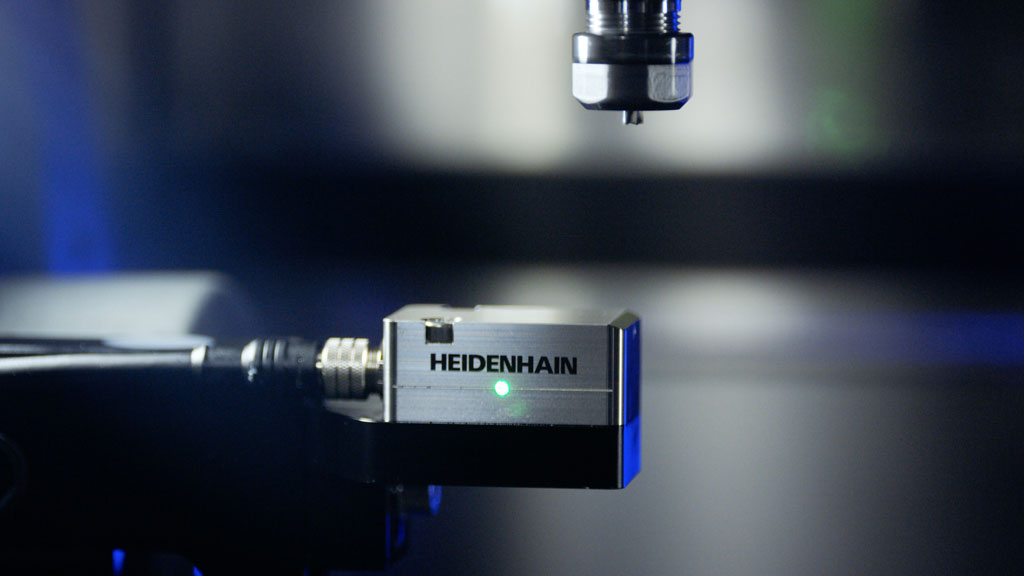

The TD 110 tool breakage detector from HEIDENHAIN: convenient in-process tool inspection

Automatically detect broken tools in automated processes and prevent damage during subsequent machining operations. The TD 110 increases process reliability without interrupting machining by detecting broken tools passing by on their way to or from the tool magazine, thereby preventing them from being used in the first place. This compact and robust sensor can be added to the workspace of any machine tool in close proximity to the machining table. Its signals are sent to the control via the touch-probe interface. The control then triggers a machine message, NC stop or a reaction defined by the user, such as a message to StateMonitor.

The TD 110 tool breakage detector inspects tools with a diameter of at least 0.4 mm and performs non-contact breakage detection starting with a length change of 2 mm. This happens inside the machine envelope with the spindle rotating at its operating speed. This considerably increases the process reliability and shaves up to six seconds off of every inspection compared with conventional laser systems. The time and cost benefits during tool changes are considerable. And because the TD 110 operates without compressed air, its carbon footprint is small. Installation is also easy thanks to the omission of air hoses and filter systems. All that’s needed instead is a single cable carrying both power and communication. And thanks to its inductive measurement technology, the TD 110 is maintenance-free.

Live demo at EMO: “The TD 110, TNC7 and StateMonitor software from HEIDENHAIN”

The live product demonstrations on the machine at the HEIDENHAIN trade-show booth in Hannover, Germany, include a demonstration of the TD 110 using the breakage inspection cycle of the TNC7, including an alert to the StateMonitor software from the HEIDENHAIN Digital Shop Floor. The breakage inspection cycle for HEIDENHAIN controls evaluates the inspection as follows:

- Tool intact = The production process can be continued, and a notification is sent to the control and to StateMonitor.

- Tool breakage detected = The user is free to define the desired action, such as locking the tool, interrupting the NC program, notifying the control and alerting StateMonitor. The TD 110 is also connected to StateMonitor as a signal message.

This allows relevant staff members to be informed of the breakage. Thanks to the StateMonitor messenger function, this accelerates reaction times, such as during simultaneous multi-machine operation. Connecting the sensor to StateMonitor also enables a detailed analysis of breakages over time.

The VT 121 and VTC 1.4 from HEIDENHAIN: tool inspection like with a microscope

The VT 121 vision system and the VTC 1.4 software give machine operators a clear view of a tool’s teeth from within the machine envelope, imaging them on the monitor and measuring the amount of cutter wear, just like under a microscope. These solutions prevent costly damage to the tool, workpiece and machine, lowering tool costs over the long run through precise wear mitigation and saving both time and costs through in-process automated imaging.

For visual inspection, the VT 121 camera creates close-up images of every tooth, with the option of a detailed panoramic image of the entire tool circumference. This is made possible by two on-board objectives with different viewing angles. The VT 121 vision system and the VTC 1.4 software therefore deliver wide-ranging capabilities when combined with cycles from the TNC control:

- Automation of tool testing on machines under development

- Documentation of the tool condition and wear

- Automation of breakage inspection and the locking damaged tools

- Ensuring proper tool condition prior to critical machining steps

- Checking the actual condition of the tool after expiration of its planned service life

- Analysis of the results, along with optimization of cutting parameters and part programs

Tool data management with HEIDENHAIN: synchronize tool data

Data about the tools in use are generated and needed by users at multiple points along the production process. A synchronized data pool obviously has numerous benefits:

- The unique identification of the tools prevents mix-ups and increases process reliability

- Consistent data about the tool is available on all machines

- The user always has an overview of where each tool is located

- The user can check each tool’s service life in real-time

The ETDM external tool data management system for the TNC 640 and TNC7 controls enables the connection of any external web-service-capable databases with the control’s local tool table. This can be implemented at any time through the PLC Programming helpline of the HEIDENHAIN Service team, even for older machines. The data of most tool presetters, for example, can be transferred and utilized. The data is exchanged via the corporate network after the user has identified the tool on the control using its unique code on the tool holder (a barcode, QR code or DataMatrix code) or via an RFID chip.