The new TS 750 touch probe and new grinding functions for the TNC 640

Grinding provides a path to perfect finishes. But this requires secure mastery of grinding processes and in-process monitoring of machining progress. This year, HEIDENHAIN will be a first-time exhibitor at GrindTec, presenting high-accuracy, robust solutions for machine manufacturers and operator-friendly grinding functions for the user on the TNC 640 control.

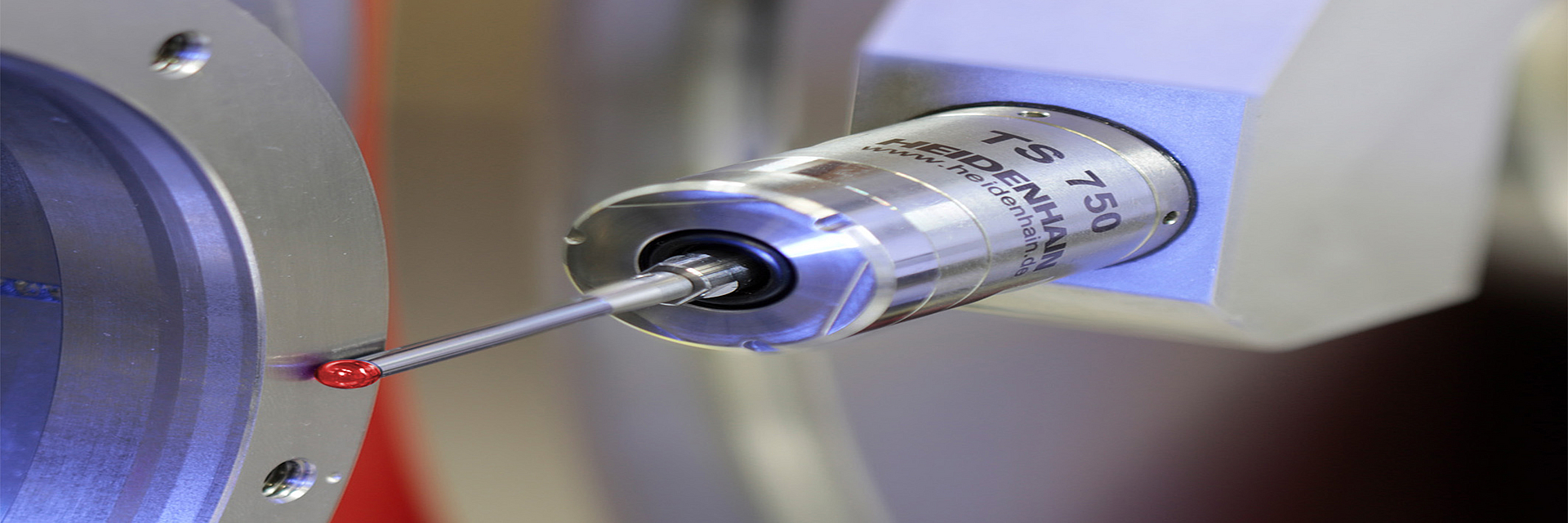

TS 750 touch probe: in-process quality inspection

The new TS 750 is a high-accuracy workpiece touch probe for grinding machines. Featuring a diameter of only 25 mm and a probing repeatability of 2σ ≤ 0.25 µm, this touch probe is both compact and highly accurate. Its radial probing force is just 0.2 N, and its long-life pressure sensor is designed to withstand several million probing operations. The touch probe’s sensors and electronics are protected by two overlying bellows that effectively keep out swarf and lubricating coolant. The outer bellows can even be replaced.

Extensive mounting options from various bases, adapters, and extensions for the M16 fastening thread, combined with a standard M3 thread for numerous stylusi, allow the HEIDENHAIN TS 750 touch probe to be adapted to a variety of measuring tasks. The TS 750 is therefore ideal for in-process part inspection inside a grinding machine. In terms of mounting, it is also interchangeable with the TS 150 optical touch probe featuring a similarly wear-free sensor.

Grinding with the TNC 640: to a perfect finish in a single setup

As a third machining operation beyond milling and turning, the TNC 640 now lets you jig grind any contour. Complete part machining via milling, turning, and grinding offers many benefits, especially for quality-intensive industries such as moldmaking and medical technology. Parts can be machined to the highest level of surface quality in a single setup, and easy-to-use standard cycles on the TNC 640 can dress grinding tools inside the machine tool. The standardized operating approach for milling, turning, and grinding makes operation particularly easy, and optimized tool management for every process supports the user during and grinding and dressing.